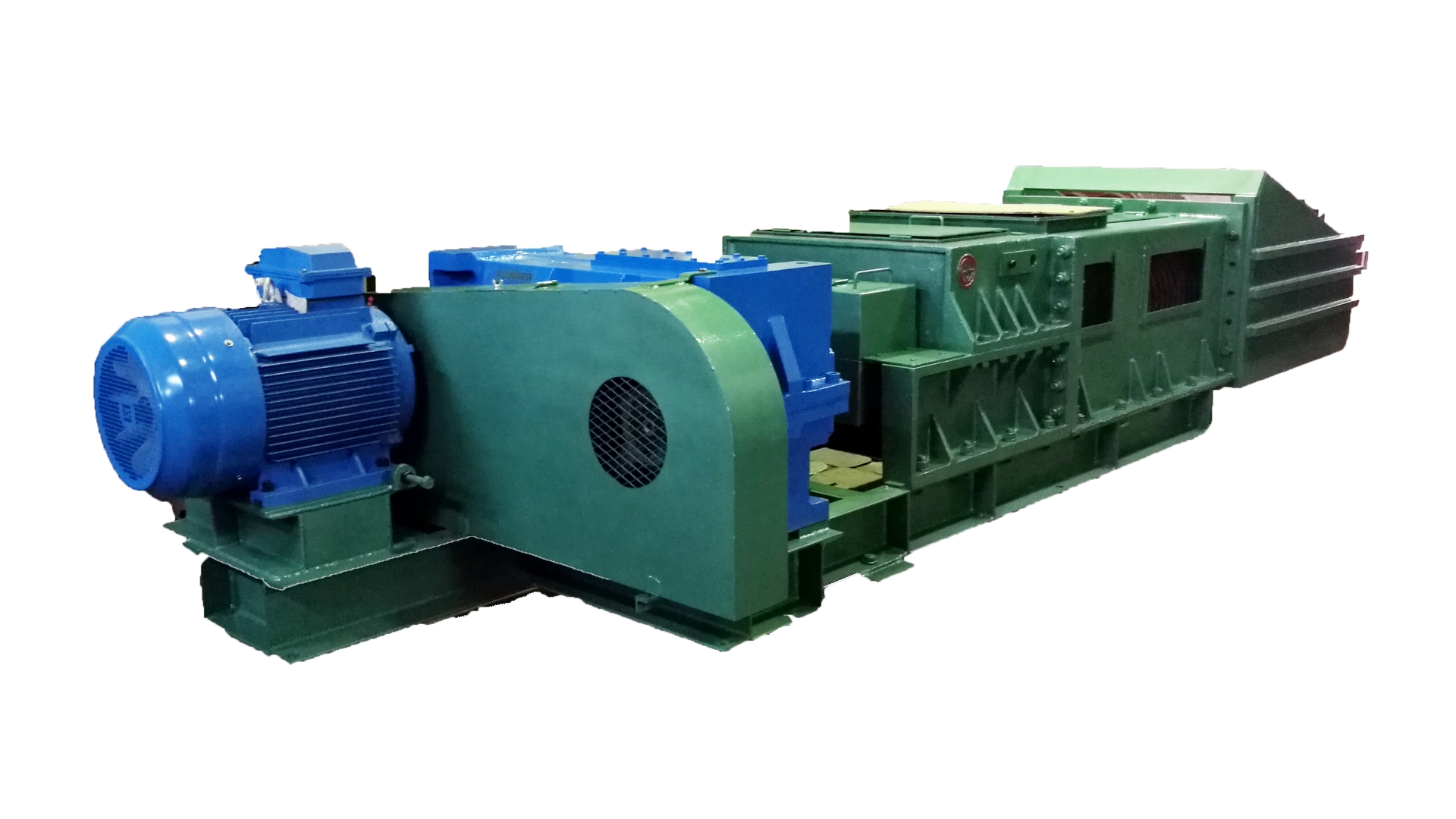

GS Twin Screw Press

MAIN FEATURES

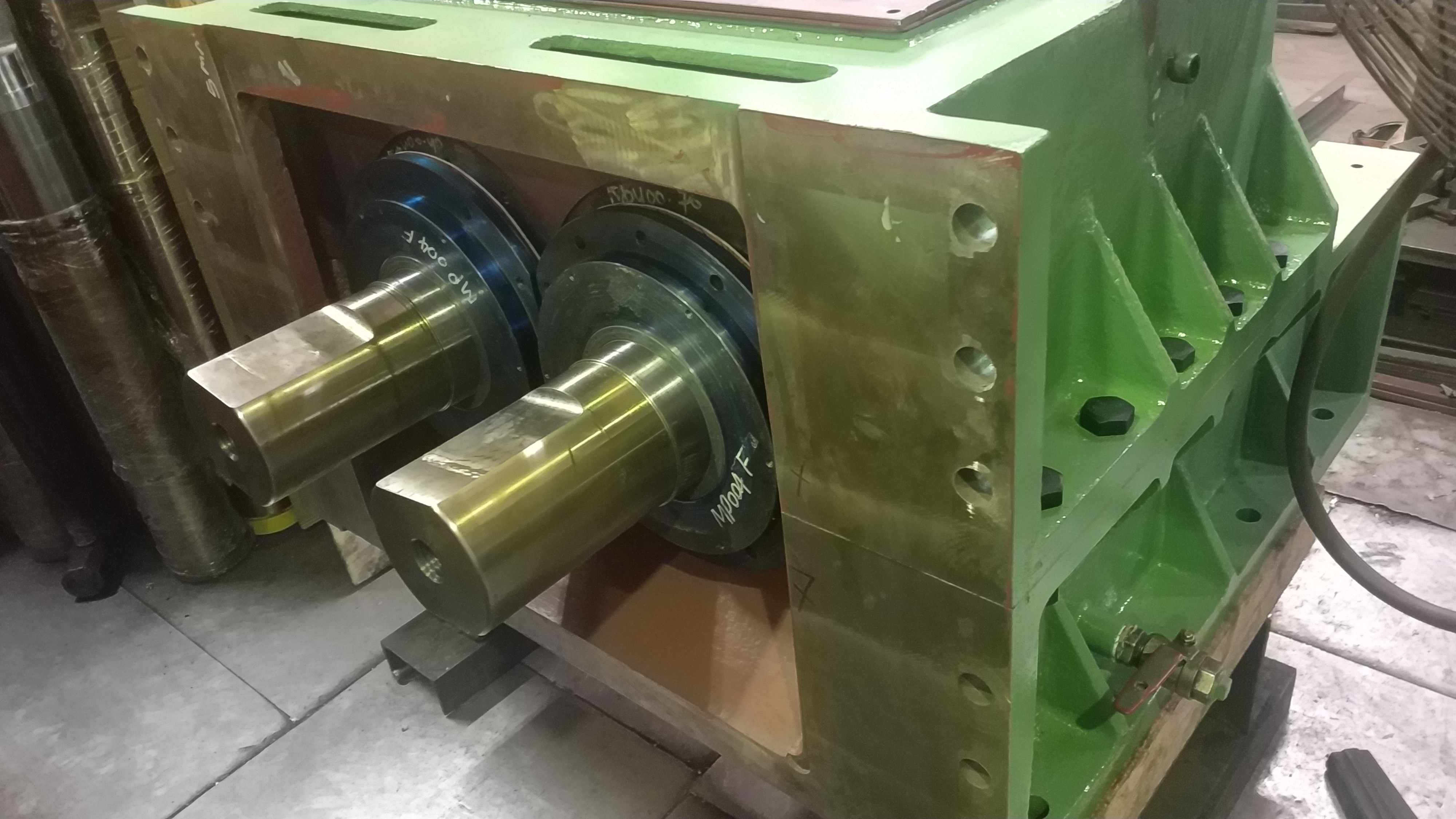

Latest Screw Press Design eliminates unpredictable component failures.

Twin Screw Press Design for better throughput.

Able to control the speed of the screw for the best end result.

Low Oil Loss on Non Oil Solid (6.5% - 7.5%).

Achieve Nut and Kernel Breakage <10%.