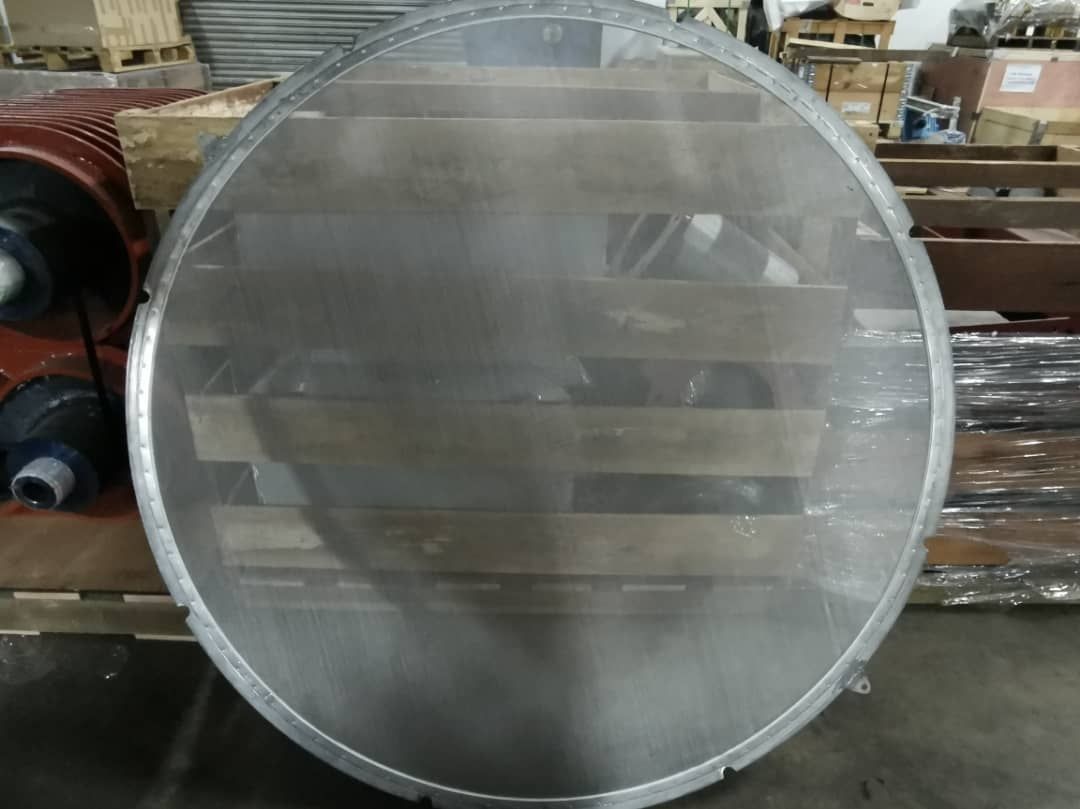

GS Vibro Screen

MAIN FEATURES

One complete single body for Vibro Energy Separator to ensure no leakage.

Specially designed for screening Crude Palm Oil or similar oil.

All contact parts manufactured in stainless steel.

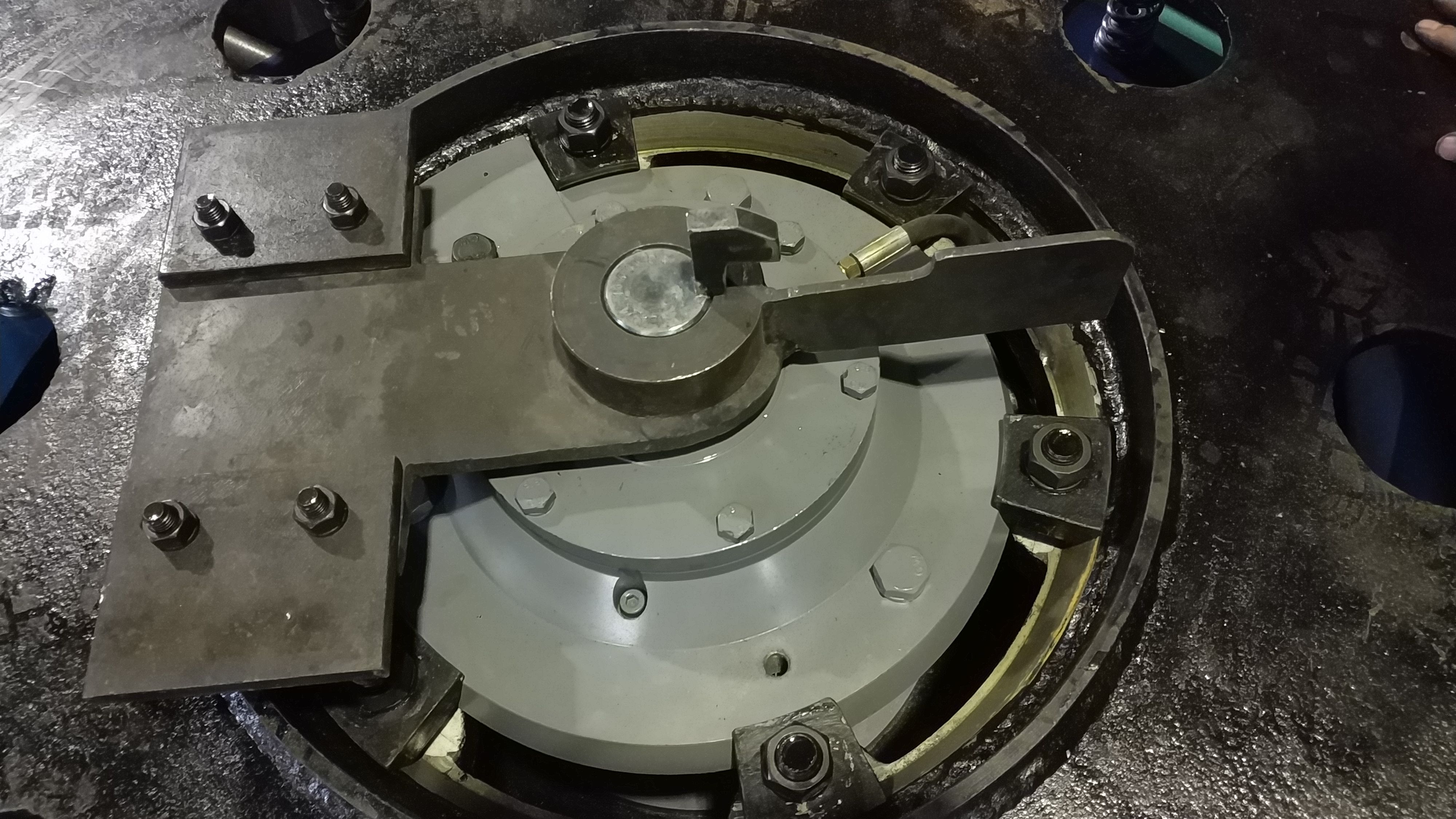

Plastic coated coil springs ensure trouble free operation.

Direct-drive vibratory motor with heavy duty bearings eliminates couplings or belts.