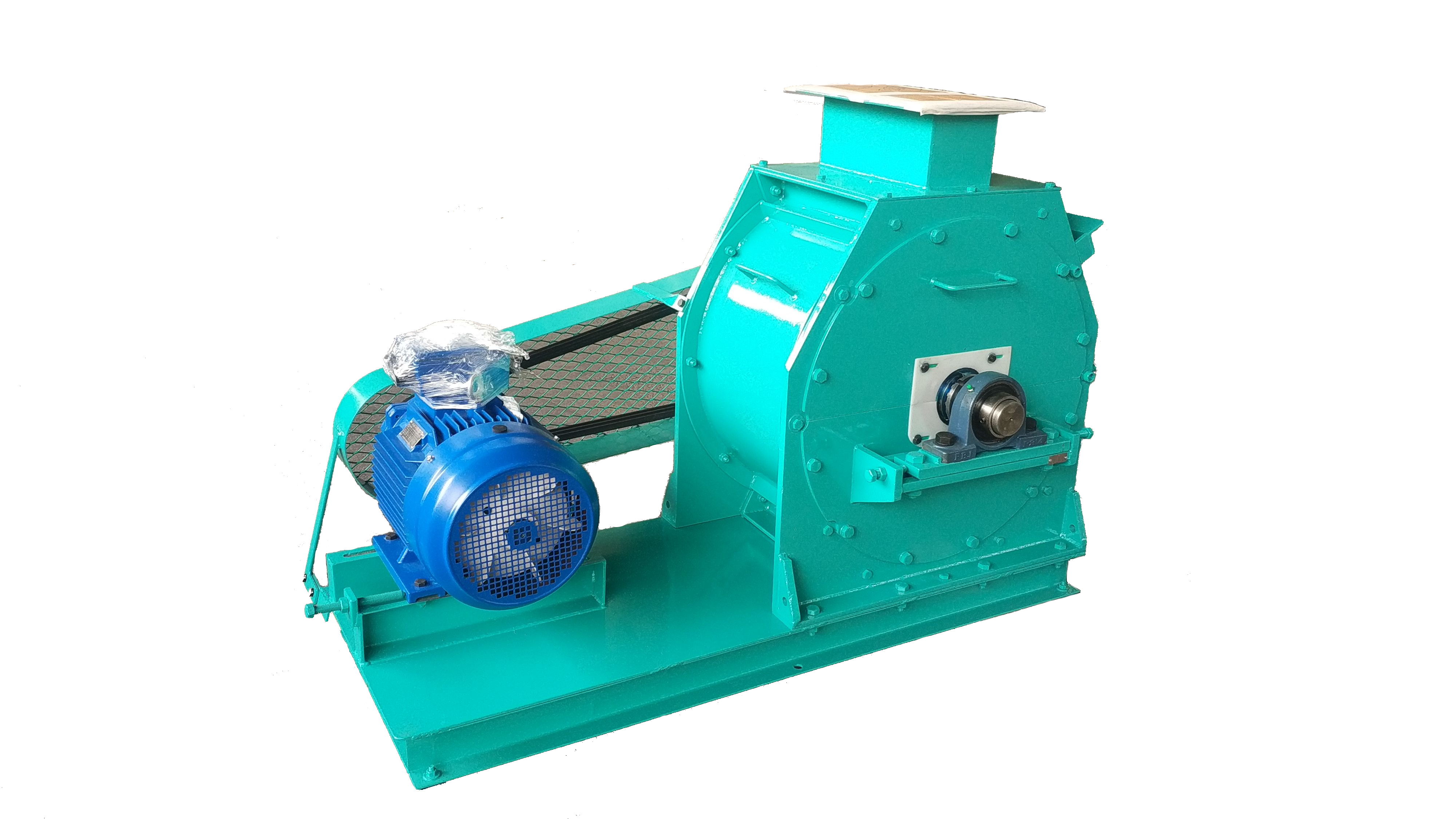

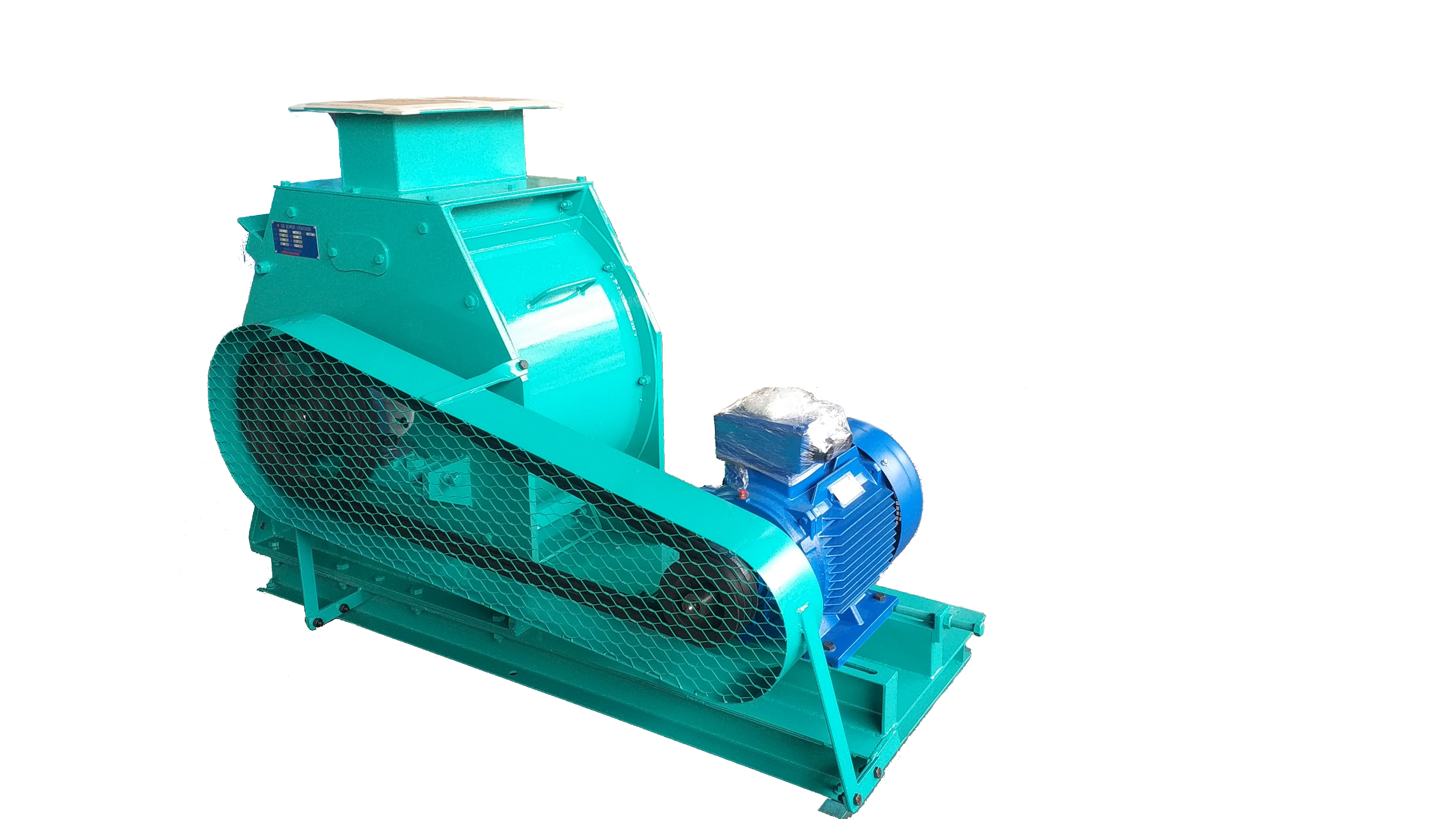

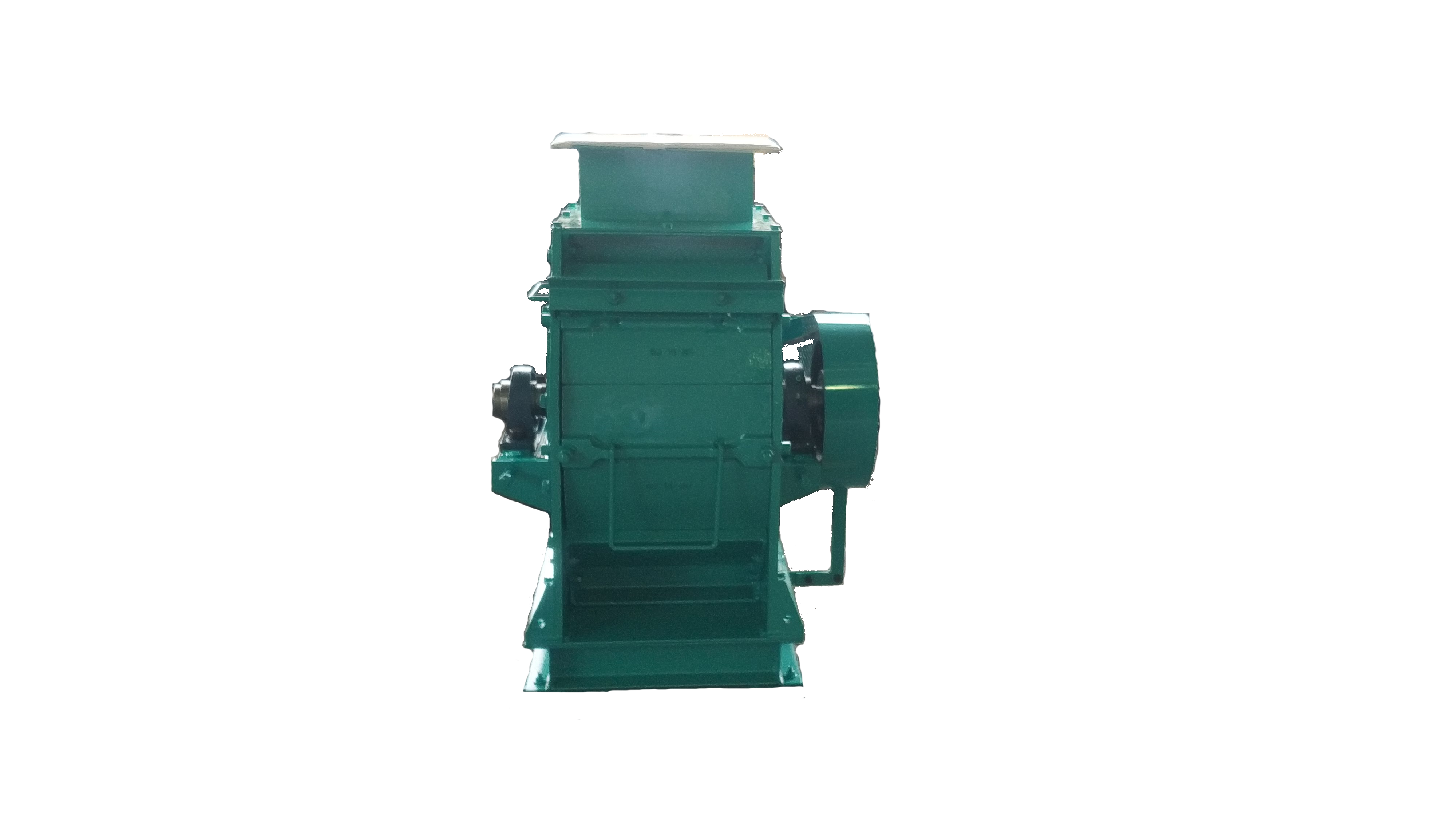

GS 8T Super Cracker

MAIN FEATURES

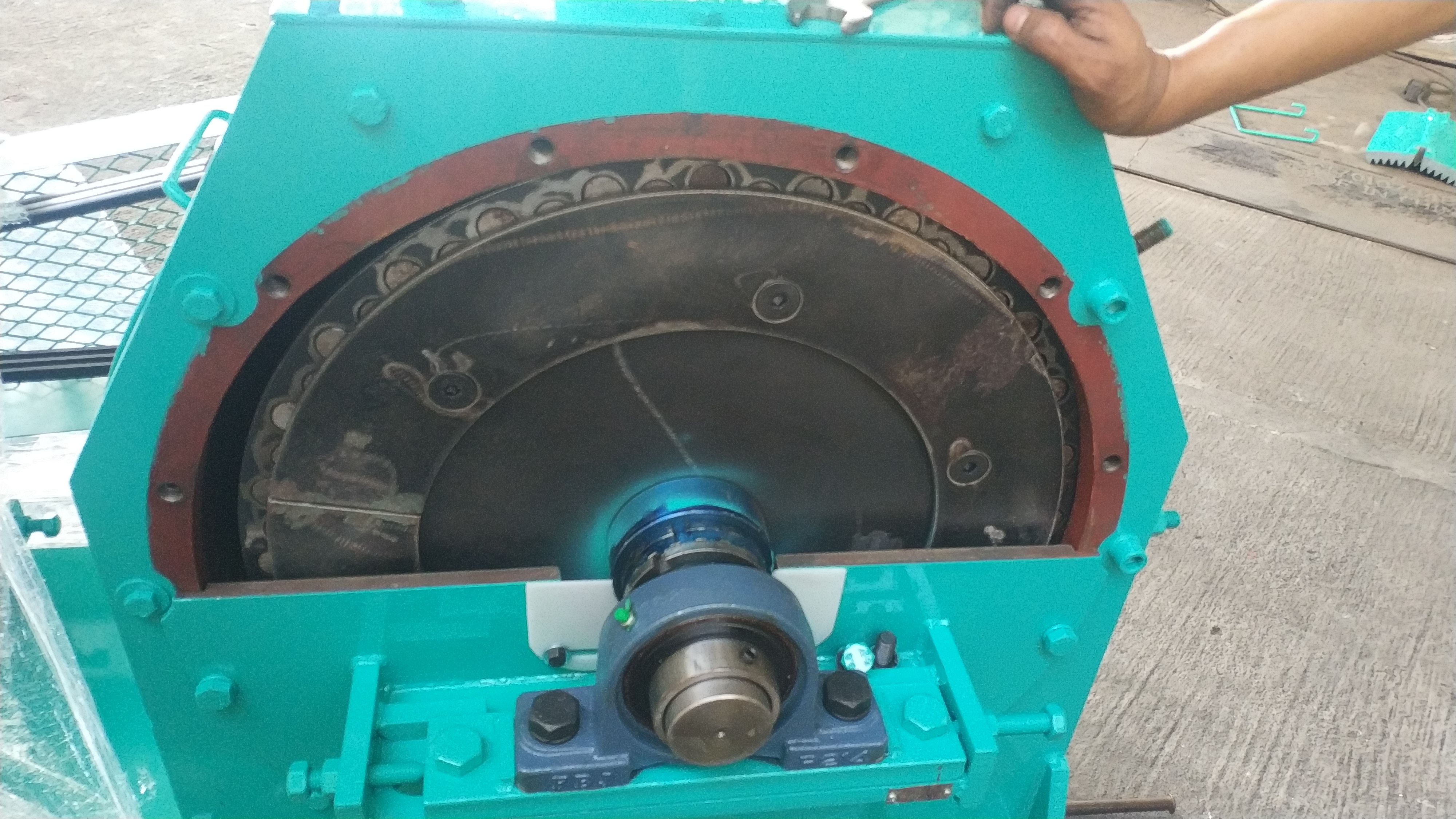

Cracking Efficiency Up to 99%.

Low Broken Kernel.

Reliable And Long Lasting Machine - Low Speed At 620-670 RPM.

Low Noise Level.

Low Vibration.